Introduction

In the current dynamic Automated Manufacturing Defect Detection environment, the importance of precision, efficiency, and quality control has reached unprecedented levels. Even minor defects can result in expensive recalls, dissatisfaction among customers, and delays in production. Conventional manual inspection techniques are often labor-intensive and susceptible to human error. This is where the integration of smart sensors and computer vision is revolutionizing the industry by automating defect detection and significantly decreasing manufacturing errors.

The Emergence of Smart Sensors and Computer Vision in Manufacturing

What are Smart Sensors?

Smart sensors are sophisticated devices that not only gather data but also analyze, communicate, and respond to information in real time. They incorporate technologies such as artificial intelligence, the Internet of Things, and machine learning to identify even the slightest irregularities in manufacturing processes.

What is Computer Vision?

Computer vision is an AI-based technology that allows machines to "see" and interpret images or videos similarly to the human eye, but with enhanced accuracy and speed. Utilizing deep learning and image recognition algorithms, computer vision systems can examine products, identify defects, and maintain quality consistency across the production line.

How These Technologies are Minimizing Manufacturing Errors

1. Immediate Defect Detection

Traditional inspection techniques depend on human operators manually examining products, which can lead to errors due to fatigue. In contrast, smart sensors and computer vision systems function continuously without fatigue, assessing each product in real time for any discrepancies, such as:

- Scratches, dents, or deformities.

- Incorrect assembly or misalignment.

- Variations in color, shape, or texture.

- Surface imperfections like cracks or impurities.

By promptly identifying defective items, manufacturers can prevent flawed products from reaching consumers and reduce waste.

2. Precision Exceeding Human Abilities

While human inspectors may overlook minute defects, AI-driven computer vision excels in identifying them with remarkable precision. The integration of high-resolution cameras and deep learning algorithms enables these systems to detect flaws as small as sub-millimeters, which would be undetectable to the human eye.

3. Minimizing Production Line Interruptions

Unforeseen defects can hinder production lines and elevate operational expenses. Predictive maintenance, facilitated by intelligent sensors, assists manufacturers in circumventing these challenges by continuously monitoring machinery performance. When a machine exhibits early signs of wear or misalignment, the system can automatically issue maintenance alerts, thereby minimizing unplanned interruptions and enhancing overall efficiency.

4. Improving Quality Consistency

Ensuring product uniformity is crucial, particularly in sectors such as automotive, electronics, and pharmaceuticals, where precision is imperative. Computer vision technology guarantees that each item produced adheres to strict specifications, thereby eliminating inconsistencies that may arise from human error.

5. Data-Driven Insights for Ongoing Enhancement

By gathering and analyzing extensive production data, intelligent sensors and computer vision yield critical insights into error trends and underlying causes. Manufacturers can leverage this information to:

- Enhance production processes

- Minimize waste and material expenses

- Boost supply chain efficiency

- Elevate overall product reliability

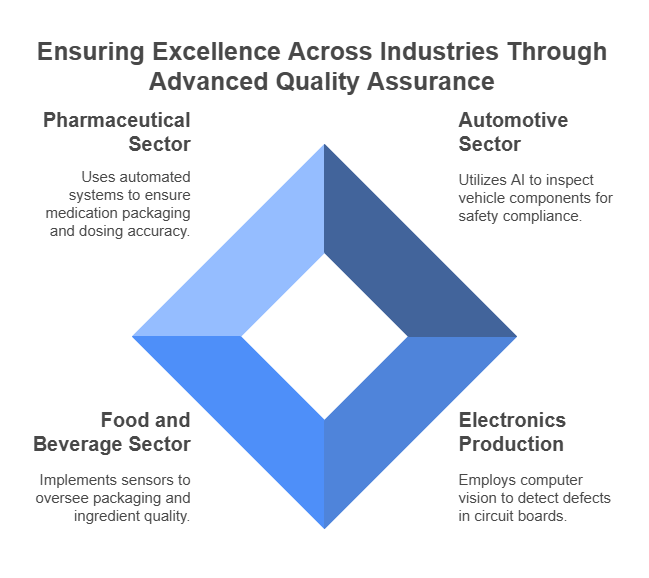

Practical Applications of Smart Sensors and Computer Vision

1. Automotive Sector

Automobile manufacturers employ AI-enhanced cameras and sensors to scrutinize components such as engine parts, chassis, and paint finishes, ensuring that vehicles comply with safety regulations prior to leaving the production facility.

2. Electronics Production

Computer vision meticulously inspects for micro-cracks, misaligned circuits, and soldering defects in Printed Circuit Boards (PCBs), preventing defective devices from entering the market.

3. Food and Beverage Sector

Intelligent sensors oversee packaging, labeling, and ingredient quality to guarantee adherence to health regulations and mitigate contamination risks.

4. Pharmaceutical Sector

Automated defect detection verifies that medications, tablets, and vials conform to stringent quality standards by pinpointing discrepancies in dosage, packaging, or labeling.

Conclusion

The incorporation of smart sensors and computer vision is transforming contemporary manufacturing by minimizing defects, boosting efficiency, and ensuring consistent product quality. By reducing human error, increasing precision, and offering real-time insights, these Global Technosol are paving the way for a future characterized by flawless, rapid, and cost-efficient production.

Comments on “How Smart Sensors and Computer Vision are Reducing Manufacturing Errors”